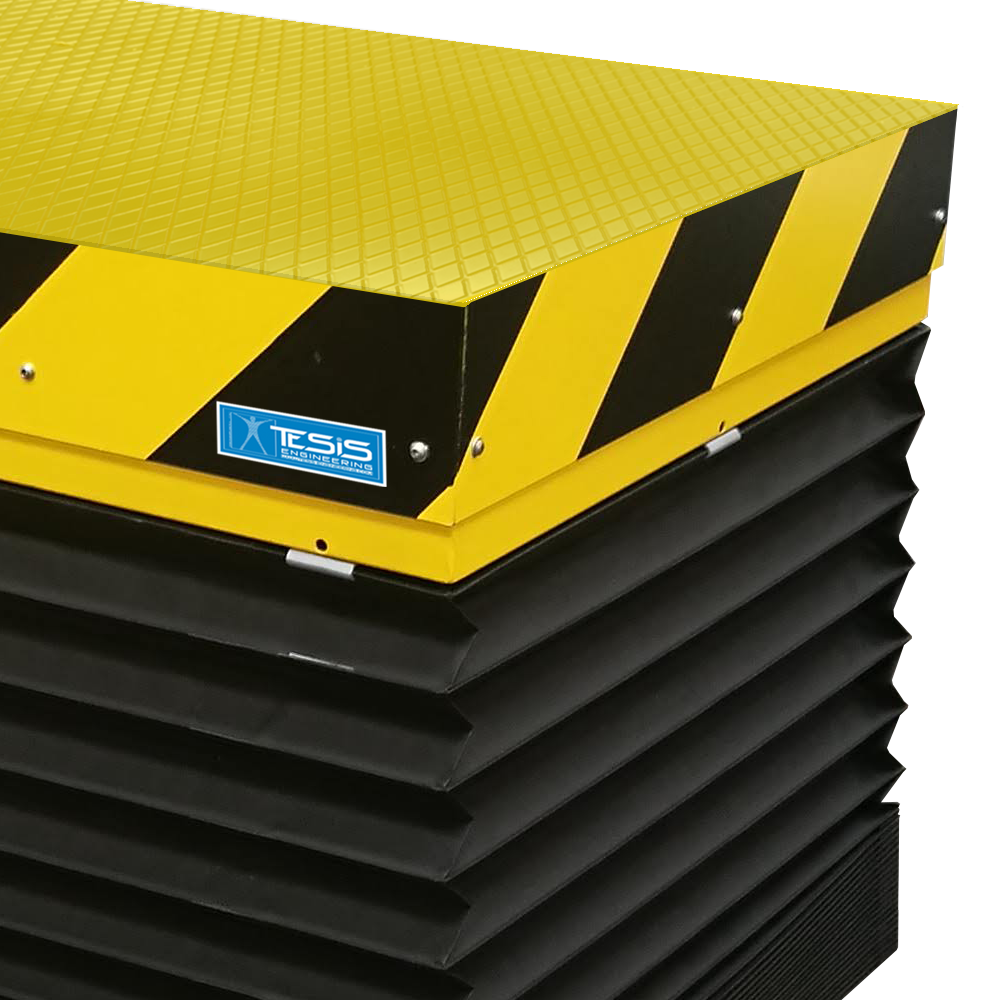

XN Series Single Scissor Lift Tables

XN Series lift tables are available in a wide variety of possible configurations, with load capacity and dimensions for tailor-made solutions.

A range of basic standard configurations, with load capacity from 600 to 10,000 kg and various platform size can be found in the table below.

XN Series lift tables can be customized to suit specific use requirements, even for heavy duty and intensive use.

Various configuration options combined with a wide range of accessories, offer an extensive choice of variations.

Designed industrial applications, TESIS Engineering lifting tables are versatile and robust: built to guarantee the highest quality and safety standards.

Compliance with European Standard EN 1570 – CE certified

XN Series Lift Tables technical data and standard features

Lift Type: Single scissor lift table with electro-hydraulic drive

Load capacity: basic models as table below or on request (range 200 kg to +80 t)

Platform dimensions: basic models as table below or on request

Structural sizing: designed for distributed or partially concentrated loads

Supply voltage: Three-phase 400V / 50Hz

Control and auxiliary circuit voltage: 24 V

Degree of protection: IP54

Controls: portable control panel (Up button / Down button)

Power unit: built-in or external (3m standard connection)

Operation: up to 30 cycles/hour x 8 hours/day

Service conditions: indoors +5°C / +40°C

Scissor legs: contoured profile in solid metal (no tubular)

Leg rollers: in solid steel

Pivot points: all equipped with self-lubricating bushings

Cylinders: single acting cylinders with chrome plated piston rod

Hydraulic components: high-performance and heavy-duty components

Standard packaging: pallet + wrapping

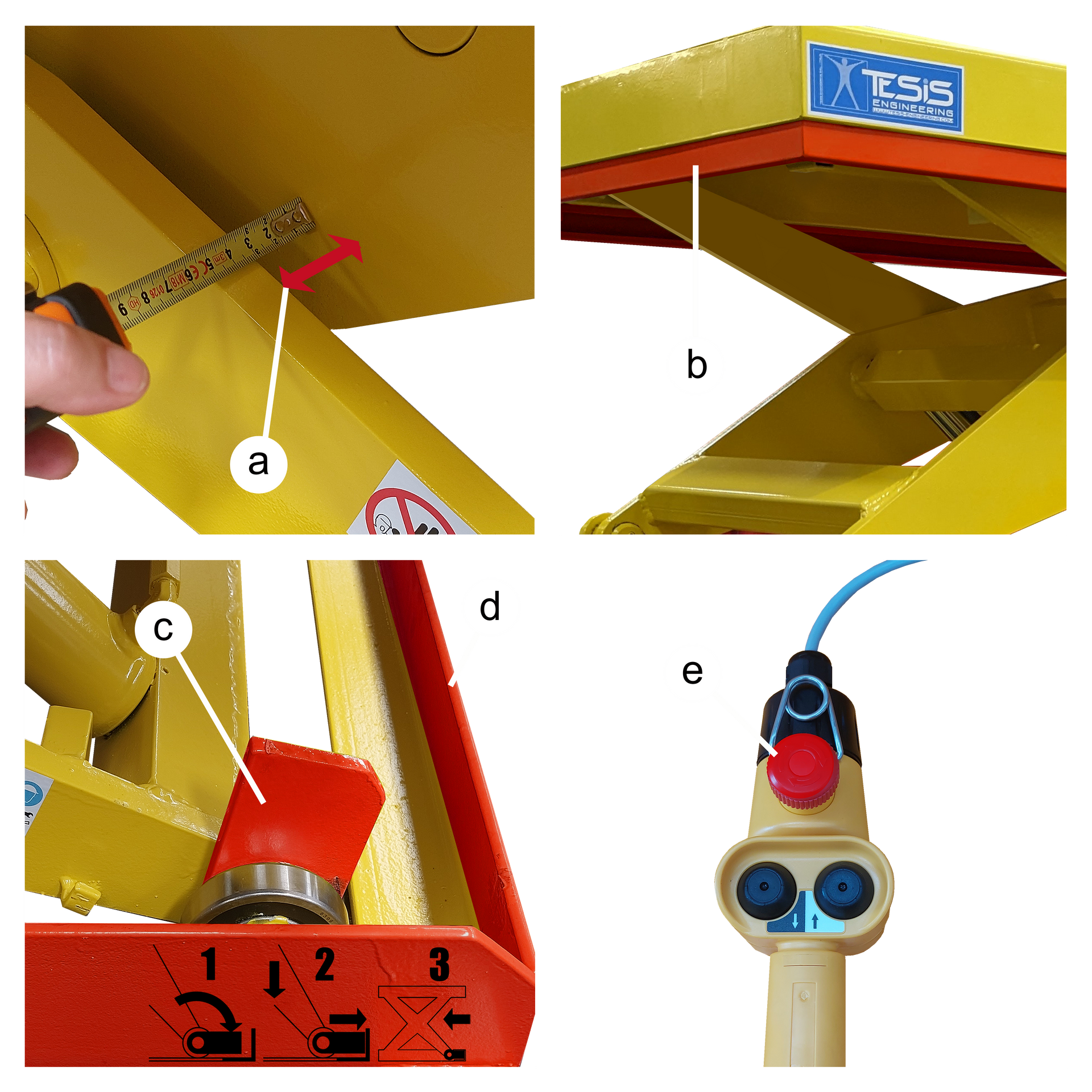

XN Series Lift Tables safety features and equipment

- Safety distance between scissor legs (a)

- Sensing edge under the entire platform contour (b)

- Built-in mechanical safety chocks for maintenance operations (c)

- Toeguard band around the entire base (d)

- Emergency stop button on the control panel (e)

- Hold-to-run controls (operation by constant pressure)

- Rupture-valve on the hydraulic circuit (prevents table free fall in case of massive fluid spillage or hydraulic failure)

- Pressure relief valve (hydraulic overload relief)

- Compensated flow control valve (lowering speed control)

- Manual lowering recovery (from the power unit)

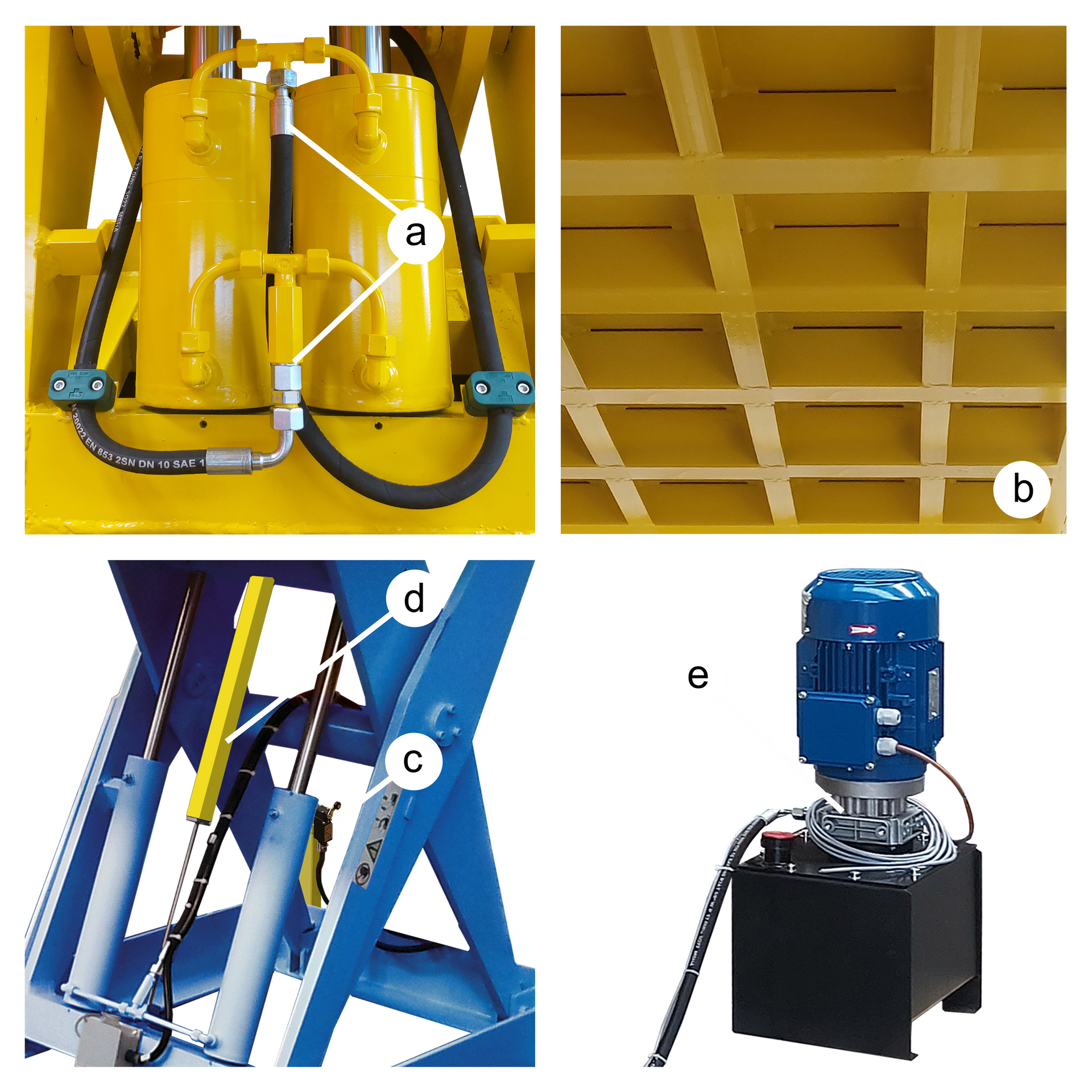

XN Series Lift Tables configuration options and customizations

- Structural sizing for concentrated, off-center or moving loads

- Package for intensive or heavy-duty applications

- Pivot points mounted on bearings

- Double acting or full-filling cylinders (a)

- Structural strengthening of the platform for the transit of vehicles and forklifts (b)

- Travel limit switches (c), encoder (d) and provisions for integration into automation systems

- External control unit (e)

- Selection of components from a range of major brands

- Customized valve assembly for applied equipment management

- Implementation for outdoor installation

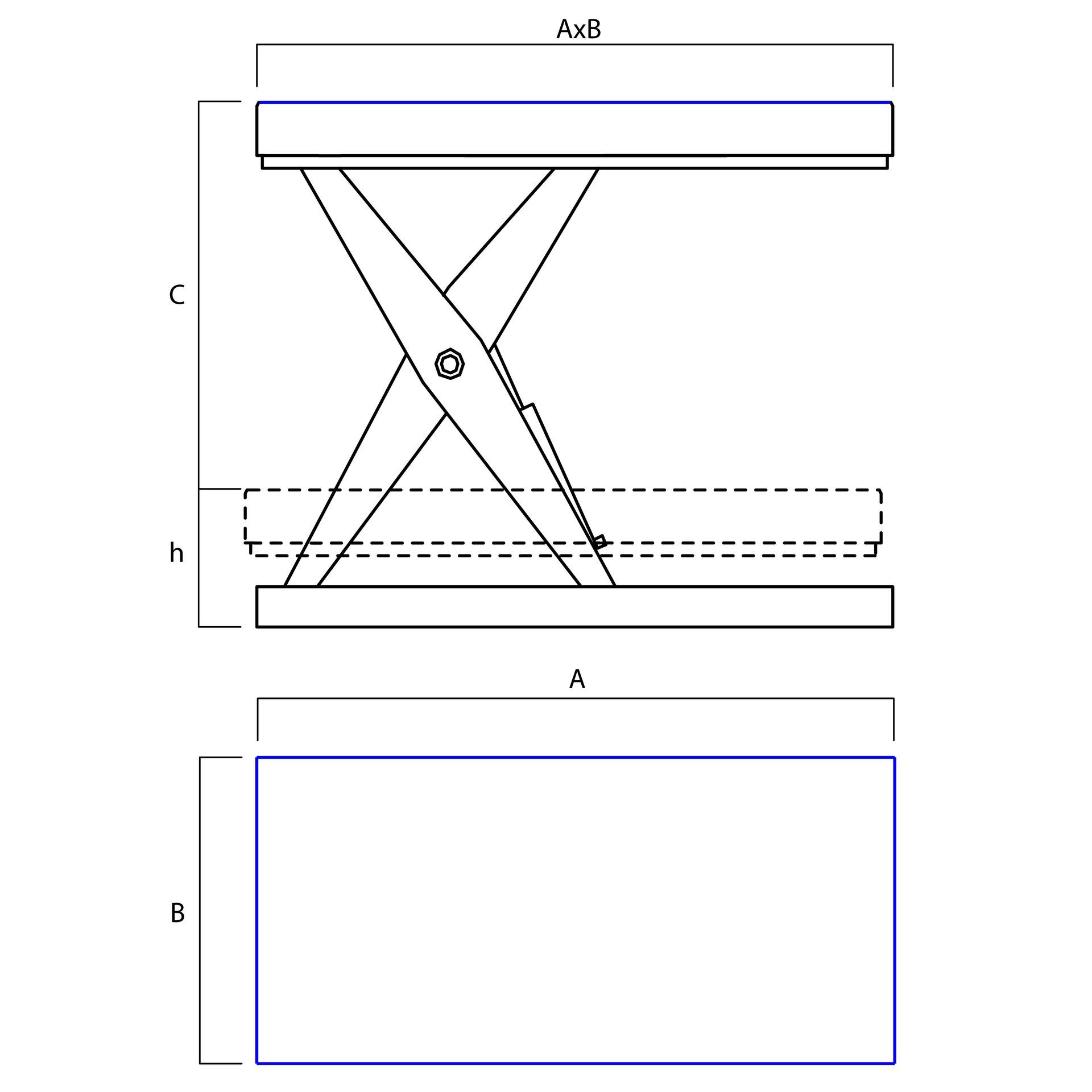

h = minimum height, C = vertical travel, AxB = platform dimensions (see dimensional scheme in Data and specification sheet), * = available only with external power unit

| XN Series | 600 kg | 1.000 kg | 2.000 kg | 3.000 kg | 4.000 kg | 5.000 kg | 6.000 kg | 8.000 kg | 10.000 kg |

|---|---|---|---|---|---|---|---|---|---|

| A x B (mm) | h / C (mm) | h / C (mm) | h / C (mm) | h / C (mm) | h / C (mm) | h / C (mm) | h / C (mm) | h / C (mm) | h / C (mm) |

| 1000 x 600 | 200* / 600 | 215* / 600 | 250* / 600 | - | - | - | - | - | - |

| 1000 x 800 | 200 / 600 | 215 / 600 | 250 / 600 | - | - | - | - | - | - |

| 1000 x 1000 | 210 / 600 | 220 / 600 | 260 / 600 | - | - | - | - | - | - |

| 1250 x 600 | 225* / 800 | 235* / 800 | 270* /800 | - | - | - | - | - | - |

| 1250 x 800 | 225 / 800 | 235 / 800 | 270 / 800 | 270* / 770 | 330* / 750 | 350* / 700 | - | - | - |

| 1250 x 1000 | 230 / 800 | 245 / 800 | 270 / 800 | 270* / 770 | 330* / 750 | 350* / 700 | 405* / 700 | - | - |

| 1250 x 1200 | 230 / 800 | 245 / 800 | 280 / 800 | 270 / 770 | 330* / 750 | 350* / 700 | 405* / 700 | - | - |

| 1550 x 600 | 235* / 1050 | 250* / 1050 | 280*/1050 | - | - | - | - | - | - |

| 1550 x 800 | 235 / 1050 | 250 / 1050 | 280 / 1050 | 290 / 1050 | 340 / 1000 | - | - | - | - |

| 1550 x 1000 | 245 / 1050 | 250 /1050 | 280 / 1050 | 290 / 1050 | 340 / 1000 | 360 / 1000 | 415 / 950 | 500* / 900 | - |

| 1550 x 1200 | 245 / 1050 | 260 / 1050 | 280 / 1050 | 290 / 1050 | 340 / 1000 | 360 / 1000 | 415 / 950 | 500* / 900 | 520* / 900 |

| 1550 x 1500 | 245 / 1050 | 260 / 1050 | 280 / 1050 | 290 / 1050 | 340 / 1000 | 360 / 1000 | 415 / 950 | 500* / 900 | 520* / 900 |

| 2000 x 1000 | 300 / 1350 | 310 / 1350 | 330 / 1350 | 350 / 1350 | 390 / 1300 | 430 / 1300 | 470 / 1250 | 540 / 1200 | - |

| 2000 x 1500 | 300 / 1350 | 310 / 1350 | 330 / 1350 | 350 / 1350 | 390 / 1300 | 430 / 1300 | 470 / 1250 | 540 / 1200 | 600 / 1200 |

| 2000 x 2000 | 310 / 1350 | 310 / 1350 | 330 / 1350 | 350 / 1350 | 390 / 1300 | 430 / 1300 | 470 / 1250 | 540 / 1200 | 600 / 1200 |

| 2500 x 1000 | 320 / 1680 | 330 / 1680 | 350 / 1680 | 370 / 1680 | 440 / 1600 | 470 / 1600 | 510 / 1550 | 580 / 1500 | |

| 2500 x 1500 | 320 / 1680 | 330 / 1680 | 350 / 1680 | 370 / 1680 | 440 / 1600 | 470 / 1600 | 510 / 1550 | 580 / 1500 | 650 / 1500 |

| 2500 x 2000 | 330 / 1680 | 340 / 1680 | 350 / 1680 | 370 / 1680 | 440 / 1600 | 470 / 1600 | 510 / 1550 | 580 / 1500 | 650 / 1500 |

| 2500 x 2500 | 330 / 1680 | 340 / 1680 | 350 / 1680 | 370 / 1680 | - | - | - | - | - |

| 3000 x 1000 | 380 / 2060 | 400 / 2060 | 440 / 2060 | 450 / 2060 | 500 / 2000 | 530 / 2000 | 560 / 1950 | 630 / 1900 | - |

| 3000 x 1500 | 380 / 2060 | 400 / 2060 | 440 / 2060 | 450 / 2060 | 500 / 2000 | 530 / 2000 | 560 / 1950 | 630 / 1900 | 700 / 1900 |

| 3000 x 2000 | 380 / 2060 | 420 / 2060 | 440 / 2060 | 450 / 2060 | 500 / 2000 | 530 / 2000 | 560 / 1950 | 630 / 1900 | 700 / 1900 |

Data and characteristics are indicative and non-binding and may be subject to change without notice

XN Series Lift Tables - ACCESSORIES

- Checker or striated non-slip platform surface; covering tops in stainless steel, aluminum or rubber

- Access or inspection hatch in platform top

- Bellow skirting under the platform

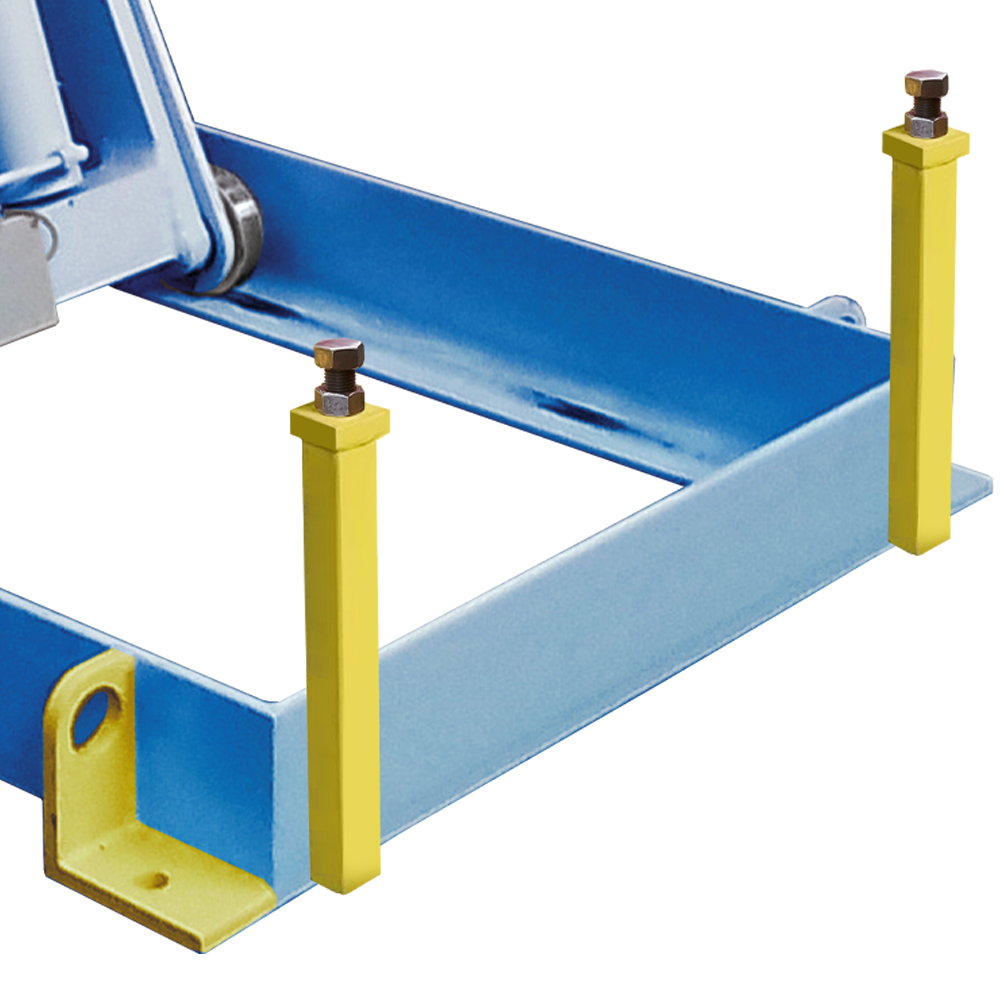

- Base supporting posts for closed platform

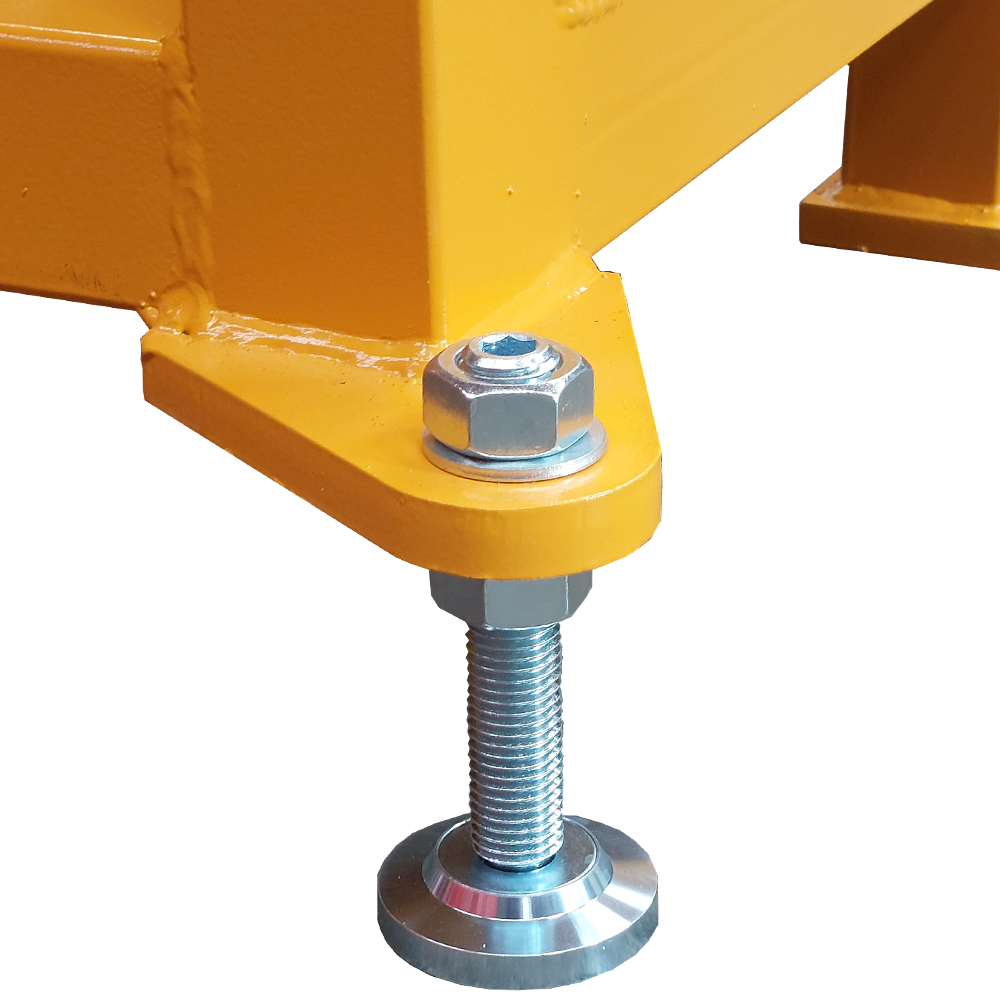

- Level adjusting posts on reinforced base

- Floor fixing plates or angles

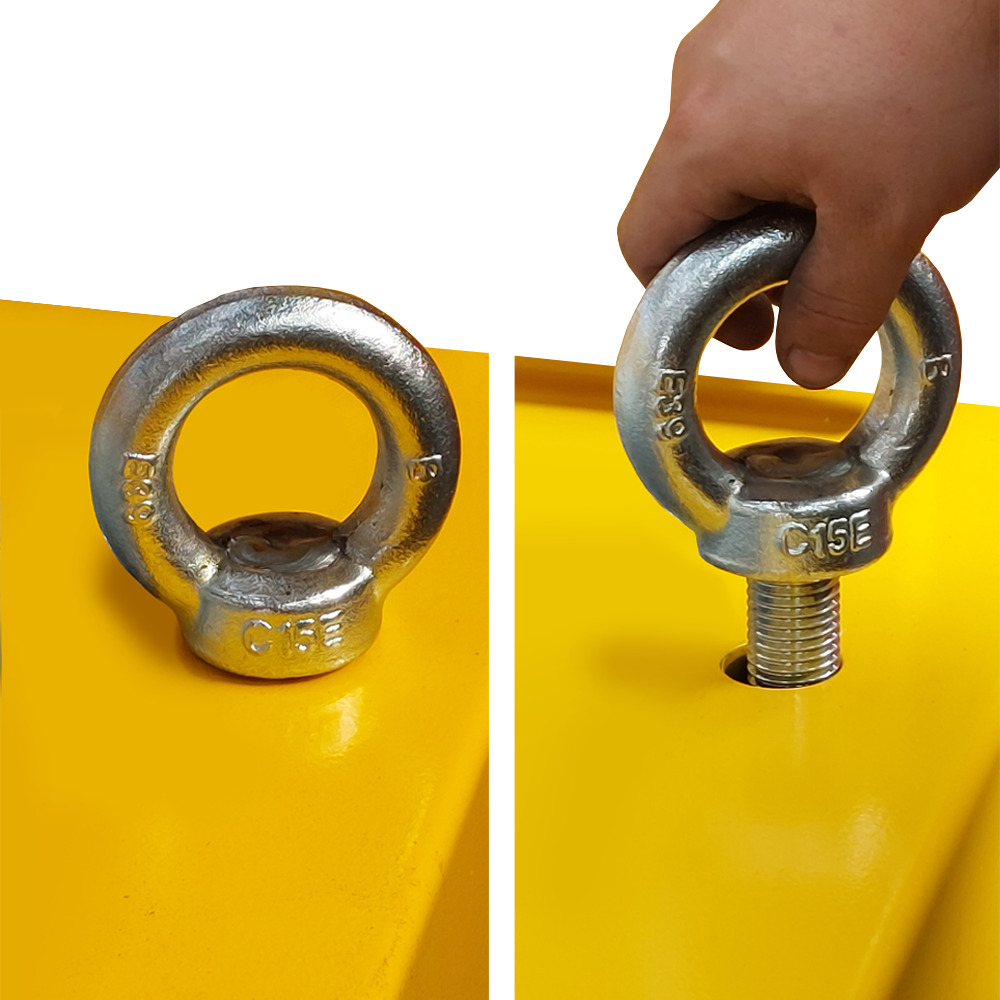

- Forkable base, eyebolts or brackets for handling

- Wheeled base, stabilizers, push bar or handle

- Fixed or hinged side edges, approach ramps

- Fixed or removable guard-rails, access gates

- Push-button panel with enabling key, wall-mounted push-button panel, foot controls, floor stand for push-button panel

- Special packaging, wood boxes and crates

Tesis Engineering Srl - All Rights Reserved